|

Frodo - a 10 inch travel Dobson10 inch, f/4.8 newtonian |

|

Telescope Making

Telescope MakingWeb Ring |

|

Next |

Previous |

Random |

List Sites Next 5 | Previous 5 | Join |

|

|

|

|

|

optics hogging out smoothing the curve polishing foucault tester figuring silvering |

|

|

|

mechanics mirror cell wire spider focuser middle ring rocker box |

|

|

|

|

mirror cell |

|

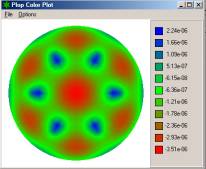

PLOP calculations suggested a

six point mirror cell would be quite sufficient for the 254 mm

(10 inch), 24 mm thickness f 4.8 mirror. |

|

|

What follows is the original version, I have since found out that there is a reason glued aluminium cells haven't found widespread use in the ATM community, yet: To unite the threefold rotational symmetry of the mirror support with the fourfold rotational symmetry of the truss assembly I chose a hexagon, made from 20 mm square aluminium tubing with four arms that connect to the lower ring. |

|

Since I wanted to make as much as possible myself and it would have been quite expensive to have the structure welded I decided to try and glue the mirror cell. I used a high strength epoxy (brandname UHU Endfest 300) and the following procedure:

- then applied the epoxy - assembled and fixed the parts with duct tape - and baked the whole thing in the oven at 180 °C for five minutes |

|

The toolbox weighs around 15 Kg and applies the force perpendicular to the glued connection. However, it cannot take a sharp blow easily. If you really want to break it, it is quite easy to do by knocking the part off with a hammer. But I hope within the usual mode of usage it is sufficiently strong. Time will tell… And time did tell... After a couple of observing sessions over the last autumn and winter I had another connection failure (one piece of the hexagon including the arm broke off) of and I decided to redo the holder for the bars from 9 mm plywood from my scrap box. This has since withstood all my destruction attempts (including rough handling of the OTA, bumping the cell rather sporty on our porch floor etc.). |

|

The three bars to hold the mirror are made from 5 mm thickness aluminium. They are glued to roller skate bearings (ABEC 5) which serve as the pivot to minimise stiction. The bearings have very small axial play so I hope when the mirror is rtv’d to the cell it won’t need lateral support. This is a necessity as I want to be able to rotate the whole OTA around the longitudinal axis, which cannot be done with the conventional cell design with a separate lateral support (sling, wire etc.) |

|

|

An additional benefit is the negative altitude capability for daytime observations (imagine your watching ships along the coastline of the Pacific ocean somewhere in New Zealand…) |

|

© 2005 by Andreas Derwahl • contact